Our clients have made more than $45M in savings, which is often validated by independent third parties (government agencies and others).

Energy savings are often more important than we might think. Many of our clients have saved more than 1 million dollars with the help of our energy efficiency projects.

Partial list of clients who have made savings with the help of Quantum Energy.

CASE STUDY NO 1

A GROCERY STORE SAVES 33% ON ITS ELECTRICITY BILL

FAR MORE IMPORTANT THAN IT SEEMS!

A typical grocery contains hundreds of motors, thousands of fluorescent tubes, about ten compressors, evaporators, condensers, control systems… the list seems infinite! The potential savings here are particularly large.

Constructed in 2006, this grocer is located in Montérégie and covers a surface area of 20,000 sq.ft. The project presented to this client included many of its systems: heating, ventilation, refrigerated and frozen counters, evaporators, condensers, compressors, control systems and electrical distribution.

Year of construction : 2006

Annual savings : 68,300 $, 33% of the total bill

Other advantages : Many new pieces of equipment under warranty, maintenance reduction, standardization of maintenance equipment, lowered noise from condensers, relocation of certain lights to meet new requirements, elimination of mercury sources, a notable visual improvement allowing for an increase in the selling value of products.

“How much would this store have to increase its sales to obtain equal value?”

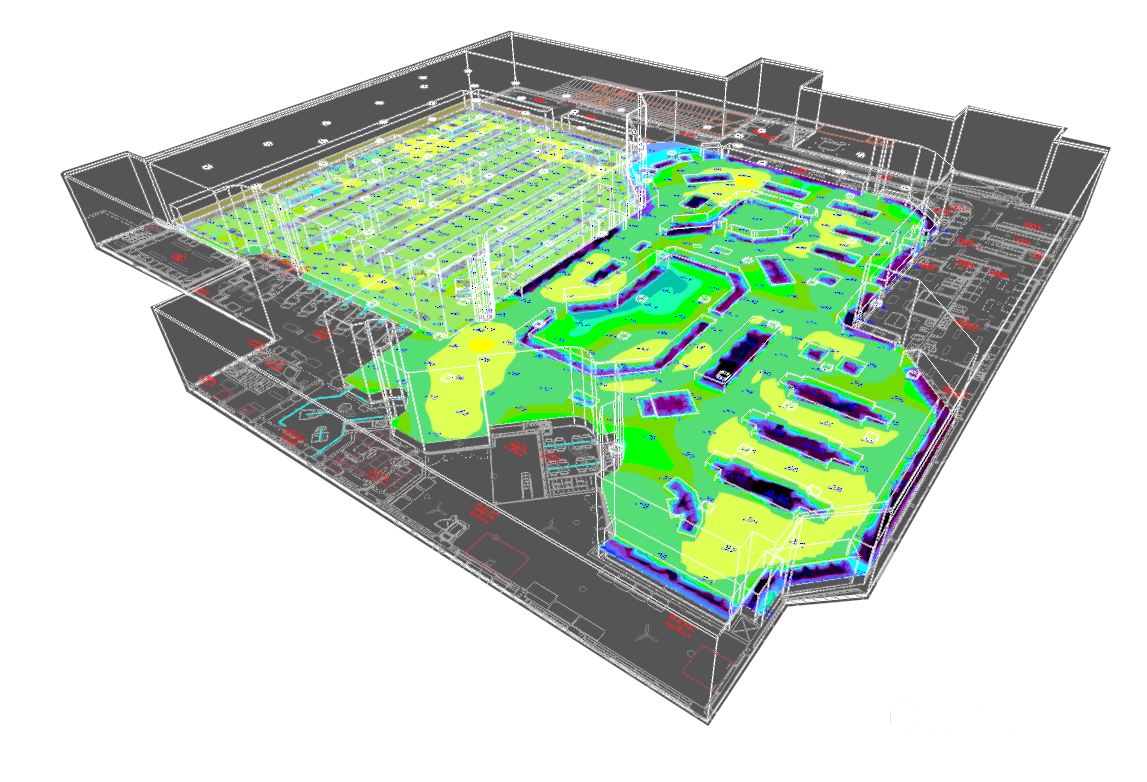

DISTRIBUTION OF ELECTRICAL CONSUMPTION AND POTENTIAL SAVINGS

Potentiel d'économies d'une épicerie Anglais

| System | ||

|---|---|---|

| TOTAL | ||

General lighting | 290 000 | 53% |

Counter | 275 000 | 76% |

Evaporator | 75 000 | 60% |

Condenser | 75 000 | 33% |

Compressor | 730 000 | 21% |

Electrical distribution | 65 000 | 54% |

Other systems | 350 000 |

CASE STUDY No 2

A FACTORY MOVES TO LED LIGHTING. IT’S POSSIBLE, ADVANTAGEOUS EVEN!

An ABB factory completely switches to LED?

This factory covers a surface area of 250,000 sq.ft and is owned by the multinational corporation ABB. This location specializes in the design and manufacturing of high voltage power transformers.

Factory lighting: All 1000W MH lights were replaced with new LED lighting. This project significantly increased the level and quality of the factory illumination while reducing the maintenance cost of light bulb replacement (1000W bulbs have an average lifespan of 12,000 hours, compared to 100,000 hours for LED lights). In operation 24/7, the maintenance of lights mounted 45 feet high proved to be a problem, considering the constant movement of the cranes.

Anti-deflagration lighting: Previous lights were replaced with LED light bulbs certified for this application.

Exterior lighting: Wall lights and projectors on the building, near crosswalks and in the parking area were replaced with LED equipment.

The new white lighting provides clearer visibility and increases the level of security for employees at night. Additionally, night guards now have greatly increased visibility when observing through surveillance cameras.

T8 and T12 fluorescent lighting : All T8 and T12 fluorescent tubes on site were replaced with high-efficiency LED lights.

Annual Savings ($) | |

Annual Savings (kWh) | |

Percentage of economy | |

Return on investment |

CASE STUDY No 3

A PROPERTY MANAGER SHORT ON FUNDS

A property manager in Quebec has 60 buildings of varying sizes under its management and wishes to reduce electrical costs. Its buildings mostly contain offices, conference halls, corridors, staircases and bathrooms. Operating hours are short. In addition, the owner has a tight budget and is looking for a quick, simple way to improve his income with little to no upfront investment.

Despite a team of owners ensuring that all systems are up to date (occupancy monitoring, T8 fluorescent lighting, etc.), nothing seemed promising. However…

Quantum Energy assembled a quick and effective project.

Annual saving | |

Return On Investment |

These numbers are in line with the expectations of the owner, but the financial situation of the company still needed to be addressed. Quantum Energy developed the project in an innovative way to compensate for the initial lack of funds. While a two-year return on investment corresponds to approximately 50% interest rate, its financing cost was less than 5%. In this way, the project was conducted without initial investment, except for monthly payments.

Since the monthly savings were substantially higher than the payments, the owner saw an immediate profit increase of several hundred thousand dollars, improving immediately his profitability.